CARTIF Projects

DIAMETER

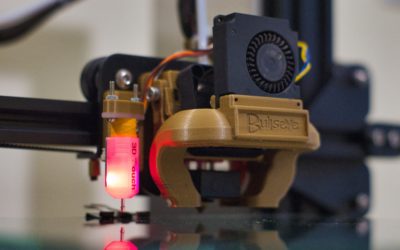

Demonstration of a sustainable circular-by-design manufacturing system based on additive manufacturing

Description

The DIAMETER project will contrast the physical-experimental results of 3D metal additive manufacturing processes with computational simulations, with the aim of predicting the behaviour of the parts under different process modifications. The analysis of mechanical responses, such as stresses and deformations, will provide in-depth knowledge of both the part and the process, identifying possible failures, reducing waste, improving quality and assessing the need to integrate post-processes, such as hybrid manufacturing combining additive and subtractive techniques.

From a combination of scenarios and results, reliable synthetic data will be generated, which will be transformed into quantifiable metrics under a sustainability approach. This data will feed an artificial intelligence-based system designed to optimise automated decision making in metal additive manufacturing configuration and procedures, thus facilitating a more efficient design from the early stages of development.

Objectives

-

- Predicting the behaviour of parts under different manufacturing conditions without the need to physically carry out each of the processes.

- Establish a hybrid manufacturing system that combines additive manufacturing and digital tools to optimise processes.

- Evaluate life cycle analyses (LCA) of products manufactured with different manufacturing systems, to identify and contrast best practices that optimise sustainability and favour the adoption of circular manufacturing models.

- Development of an AI-assisted algorithm to calculate and evaluate the ecological and economic impacts of various methods.

- Create the necessary solutions and strategies to facilitate the efficient and sustainable transition of the 3D metal manufacturing sector towards a circular economy.

Actions

-

- Develop a vision system for dimensional measurement and surface verification during the process, adapted to metal 3D printing work environments.

- Identify by means of numerical simulation critical areas of the parts under consideration and optimise their manufacturing position and the strategy of the manufacturing supports accordingly.

- Develop machine learning algorithms to predict environmental impacts based on a series of synthetic data extracted from simulations and detailed process information.

Expected Results

- Improving the quality and precision of parts.

- Optimisation of manufacturing.

- Improved sustainability.

R&D Line

- Development of AI-based solutions for decision support in construction

Partners

Horizon Europe

101177422

Total Budget: 5,999,845€

CARTIF Budget: 324,625€

CARTIF Funding: 324,625€

Duration: 01/11/2024 – 01/11/2028

Responsible

Norberto Ibán

Networking

Infrastructures projects:

CLEANPORTS

CARTIF Projects CLEANPORTSResearch of intelligent and sustainable nay solutions for the automation of logistics and advanced intermodal processes from por to last mile.DescriptionThe main objective of the project is to improve logistics processes for the complete...

INPERSO

INPERSO is a holistic project of deep renovation of buildings that address all its life cycle and combines industrialization and customization. INPERSO will integrate new technological components that joint with pre-manufacturing advantages, preintegration and 3D printing robotic will reduce drastically time and costs of the construction.

SESAMO

Design, configure, programme and adapt a system that facilitates and assists the user in their relationship with the cabinet doors.

Portable 3DPrinter

Portable 3D printer looks for the innovation in construction processes promoting the industrialization and customization of construction that 3D printing technologies provide.

Metabuilding Labs

To reach the COP21 goal of nearly-zero energy, zero emission buildings MBLabs Labs strives to unleash the innovation potential of the SMEs of the Construction sector by lowering the entry barriers to test innovative solutions in a network of testing facilities in RTOs and Living Labs in 13 countries

I-NERGY

The main objective of I-NERGY is to deliver an energy specific open modular frameork for supporting AI-on-demand in the energy sector.

I-NERGY contributes significantly to achieve a techno-economic optimal mangement of the EPES (Electric Power & Energy Services)

LIFE HUELLAS

LIFE-HUELLAS project looks for the enviroonmntal assessment of the life cycle of the rail transport to correctly assess its environmneta impact.

SORTI

The objective of the SORTI project is to develop optical systems based tools and new technologies to properly identifying, monitoring and managing of structural risks in buildings.

REZBUILD

The main objective of the REZBUILD project is to create a collaborative rehabilitation ecosystem, integrating innovative technologies, and focusing on the existing housing stock. The aim is to increase the annual rate of building renovation from the current 1% to try to reach 2.5%.

REPARA 2.0

REPARA 2.0 aims to develop new technologies and methodologies that support infrastructure management and allow the rehabilitation and conservation of any type of road at a lower economic and environmental cost.

SALUS

SALUS project appears due to the lack of techniques able to detect geomembrane damages before these cause the rupture, and therefore, the environmental pollution

WTANK

development of a new tank of more than 2000m3 by means of a new production process called ‘flex moulding’ and materialised with fibreglass reinforced polymeric composite panels (FRP) for application in the wastewater treatment sector.

REHABCAR

El proyecto REHABCAR (REHABilitación de CARreteras y autopistas) desarrolló nuevas herramientas para la transformación de las carreteras y autovías existentes en infraestructuras económicamente sostenibles y de alta calidad para prolongar su vida útil y adaptarlas a las nuevas necesidades del tráfico.