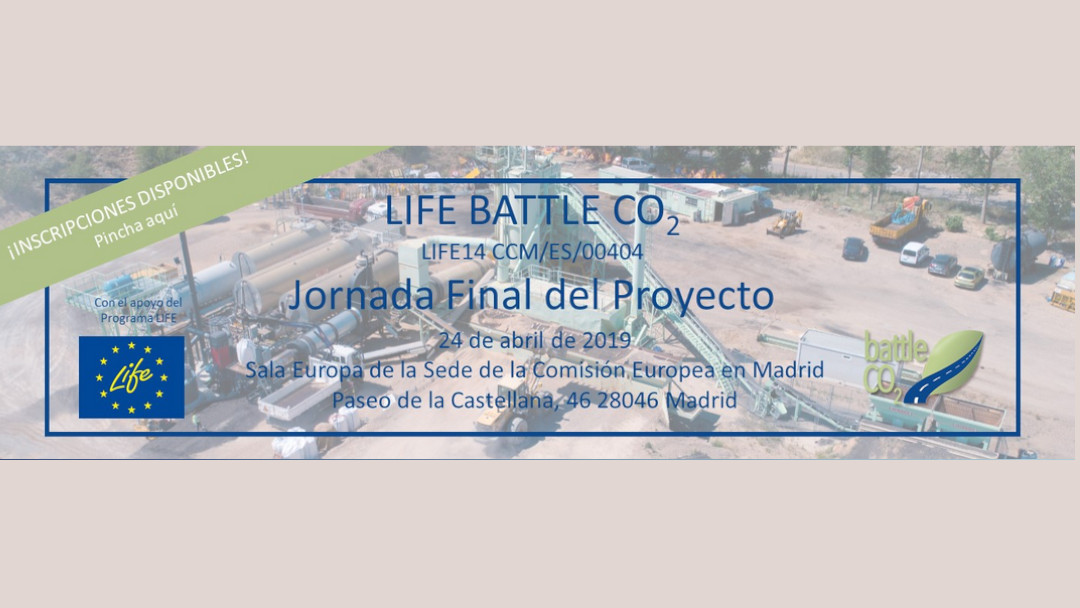

Next April 24th, the final event of the LIFE BATTLE CO2 project, led by CARTIF, will be held at the office of the European Commission in Madrid. This initiative has succeeded in replacing 80% of the fossil fuels used in the manufacturing process of the asphalt plant by biomass from sustainable forest management. The event, which will detail the results of the project, will summarize more than 3 years of work to reduce the carbon footprint in asphalt mixtures.

Asphalt mix manufacturing requires the use of a heat source that allows to reduce the viscosity of the bitumen, so that the mixture consisting of aggregates and bituminous binder has adequate handling properties. Traditionally, the heat sources come from non-renewable (fossil) energies (fuel and gas), which derivate in the corresponding greenhouse gas (GHG) emissions.

The LIFE BATTLE CO2 Project has focused on demonstrating the technical, environmental and economic feasibility of incorporating biomass, a renewable energy source with great growth potential, as an alternative fuel in the manufacturing process of the asphalt mixtures. The initiative has managed to reduce CO2 emissions by about 80% in the asphalt plant, and close to 45% in the life cycle of the asphalt mix from the raw materials to the construction work stage, achieving a more sustainable road network.

Developed in the framework of the European LIFE programme and with CARTIF at the head, the project counts with the participation of the construction company COLLOSA, in whose facilities in Cubillas de Santa Marta (Valladolid) the implementation of prototypes has been carried out to validate this new model of operation, and the support of the Spanish Road Technological Platform.