CARTIF Projects

WTANK

Development of a new system for building large-capacity modular tanks with improved properties

Description

WTANK has enabled the development of a new tank of more than 2000m3 by means of a new production process called ‘flex moulding’ and materialised with fibreglass reinforced polymer composite panels (FRP) for its application in the wastewater treatment sector. The project has increased the volumetric capacity of the tank by more than 600% compared to the initial capacity, enabling it to position itself on the international market. It also aims to establish itself thanks to its improved properties, a modular design that can be transported in containers and a simple installation that does not require major resources.

Objectives

-

- To know the real behaviour of the material in order to optimally dimension the minimum necessary thickness of the plates.

- To develop an application to verify the resistance of the tanks, depending on their volume.

- To endow the manufacturing material with photocatalytic activity.

- To build a demonstrator tank.

- Enter the international market.

Actions

-

- Mechanical characterisation of the material.

- Study and optimisation, from a mechanical point of view, of the composite material used.

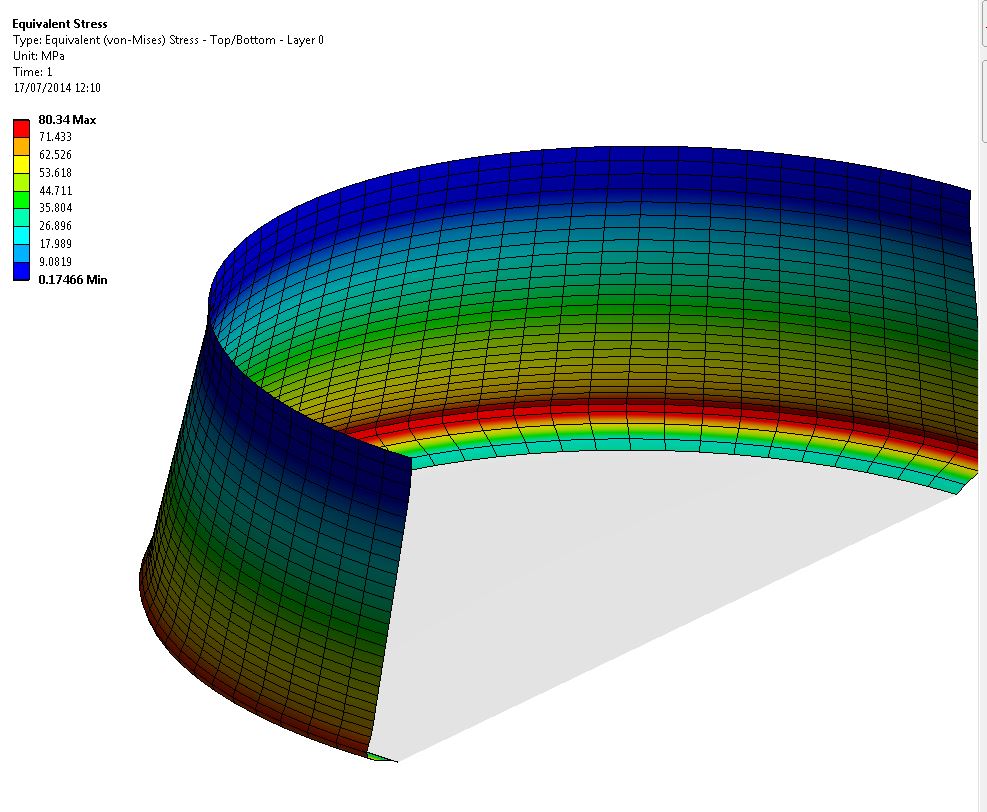

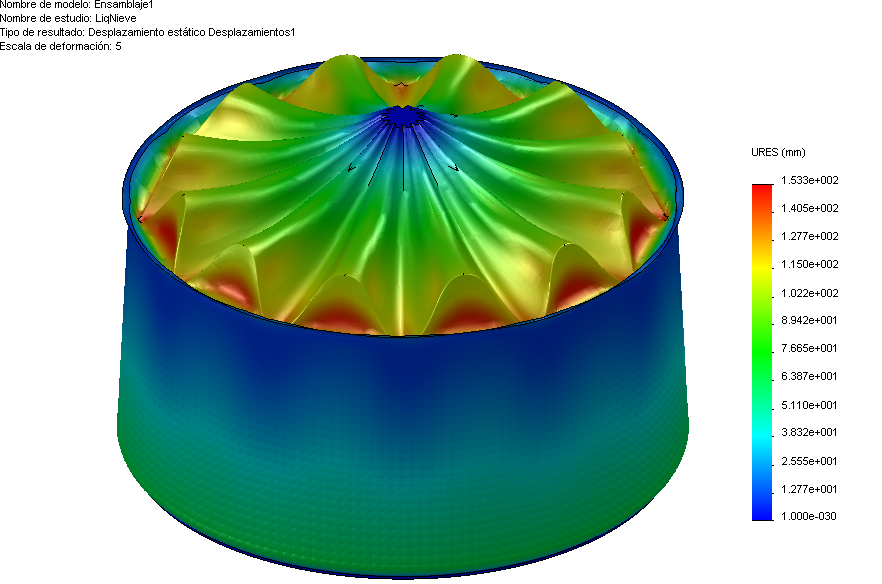

- Mechanical design of the tank, defining its technical specifications, modelling the structure and thereby evaluating the possible improvements to be introduced to improve its mechanical behaviour without affecting the production process.

- Analysis and calculation of removable joints between composite plates that make up the tank.

- Admissible coatings for the material so that it presents photocatalytic properties and avoids algae proliferation.

- Apply eco-design strategies in the manufacture of the tanks.

Expected Results

- System for the construction of large capacity modular tanks with improved properties.

- To develop an application to verify the strength of the tanks, depending on their volume.

R&D Line

- Development of designs and prototypes of new mechanical and structural systems.

Relevance

Partners

INNPACTO 2012

IPT-2012-1004-020000

Total Budget: 701,400€

CARTIF Budget: 280,000€

Duration: 01/11/2012 – 31/12/2014

Gallery

Networking

Infrastructures projects:

DIAMETER

In the DIAMETER project, the physical-experimental results of the 3D metal additive manufacturing processes will be contrasted with computational simulations, with the aim of predicting the behaviour of the parts under different modifications of the process.

CLEANPORTS

CARTIF Projects CLEANPORTSResearch of intelligent and sustainable nay solutions for the automation of logistics and advanced intermodal processes from por to last mile.DescriptionThe main objective of the project is to improve logistics processes for the complete...

INPERSO

INPERSO is a holistic project of deep renovation of buildings that address all its life cycle and combines industrialization and customization. INPERSO will integrate new technological components that joint with pre-manufacturing advantages, preintegration and 3D printing robotic will reduce drastically time and costs of the construction.

SESAMO

Design, configure, programme and adapt a system that facilitates and assists the user in their relationship with the cabinet doors.

Portable 3DPrinter

Portable 3D printer looks for the innovation in construction processes promoting the industrialization and customization of construction that 3D printing technologies provide.

Metabuilding Labs

To reach the COP21 goal of nearly-zero energy, zero emission buildings MBLabs Labs strives to unleash the innovation potential of the SMEs of the Construction sector by lowering the entry barriers to test innovative solutions in a network of testing facilities in RTOs and Living Labs in 13 countries

I-NERGY

The main objective of I-NERGY is to deliver an energy specific open modular frameork for supporting AI-on-demand in the energy sector.

I-NERGY contributes significantly to achieve a techno-economic optimal mangement of the EPES (Electric Power & Energy Services)

LIFE HUELLAS

LIFE-HUELLAS project looks for the enviroonmntal assessment of the life cycle of the rail transport to correctly assess its environmneta impact.

SORTI

The objective of the SORTI project is to develop optical systems based tools and new technologies to properly identifying, monitoring and managing of structural risks in buildings.

REZBUILD

The main objective of the REZBUILD project is to create a collaborative rehabilitation ecosystem, integrating innovative technologies, and focusing on the existing housing stock. The aim is to increase the annual rate of building renovation from the current 1% to try to reach 2.5%.

REPARA 2.0

REPARA 2.0 aims to develop new technologies and methodologies that support infrastructure management and allow the rehabilitation and conservation of any type of road at a lower economic and environmental cost.

SALUS

SALUS project appears due to the lack of techniques able to detect geomembrane damages before these cause the rupture, and therefore, the environmental pollution

REHABCAR

El proyecto REHABCAR (REHABilitación de CARreteras y autopistas) desarrolló nuevas herramientas para la transformación de las carreteras y autovías existentes en infraestructuras económicamente sostenibles y de alta calidad para prolongar su vida útil y adaptarlas a las nuevas necesidades del tráfico.